Wood is a unique material radiating warm and safety feeling through its unrepeatable impression. Manifoldness of this nature material as well as easy manipulation and maintenance will enjoy you.

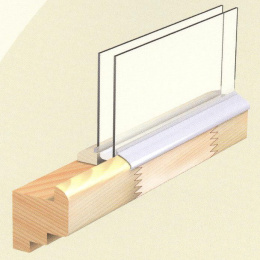

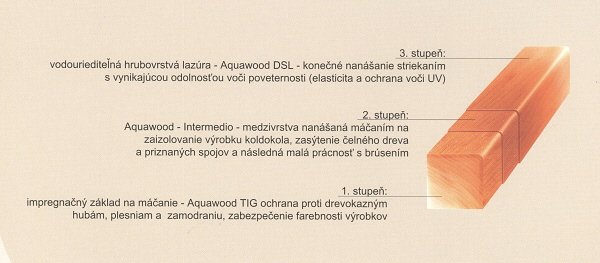

Surface treatment has been developed through the time o using of eurowindows to high quality and durability. Quality surface treatment is composing of three coatings.

First coating is called soaking coating. It is put on the ground wood usually by dipping in solution. It presents and fulfills more functions they are in direct or indirect relation with surface treatment resistance. It prepares the surface for second coating. It is bound directly to the wooden matter and it is a medium of protection. Thanks to this basic coating the wood is protected against the molds, fungus, insect or UV radiation. This basic coating is not resistant against the moisture. Protection against the water and moisture is ensured with second and third coating. Second coating, often called Intermedio, is lasur. It ensures for wood moisture resistance. Intermedio is constructed in the way to be able to be dipped or diving what ensures the penetration of agent into all cracks and corners where the moisture comes in the wood most frequently. These places cannot be protected if we put on the coating with brush or spray. It can be said that Intermedio protects the wood all the round the window contacting the outer space. Third coating – thick ply acrylic is put on by spray. Besides the moisture resistance it has to be enough soft to be able to resist to the hailstorm. It has to be elastic to resistant small measure changes caused by changing of moisture of wood.

Basic characteristics of surface treatment on windows MAKROWIN:

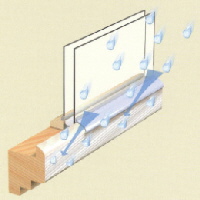

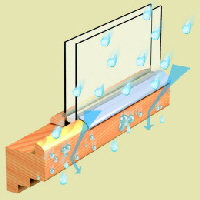

Water absorbing protection

Usually used acryl varnishes stand up the abrasion of running water /long rainy seasons/ for limited time only, after that some period the water start to leak through the varnish film, the surface turns white and looses its transparency. This is not the case for gross grained water diluted acryl MAKROWIN Aquawood DSL – generation 3: firm netting of varnish film prevents from absorbing the water for ever.

Vapor penetration

High grade of vapor penetration is advantage in all situations where the vapor is being created in inner spaces and its diffusiveness lasts the inner space as for example in winter buildings, they are heated but where the ventilation is not satisfactory. Acrylics and varnishes of Makrowin are vapor penetrable and that prevents to damages caused by moisture. In any case the ventilation has to be done regularly!!!

Elasticity

Surface treatment on MAKROWIN windows is known with high elasticity. Acrylic film of gross grain acrylic layer can be stretched to double of its size. This enables the fact that wood in the process of swelling and drying is permanent connected with varnish film – there is no danger of micro cracks even if temperature fluctuates drastically.

Excellent adhesion on moisture wood

Even if wood has high moisture content /during longer rain seasons or constant high room moisture/ the acrylics and varnishes of generation 3 keep their adhesion to the surface.

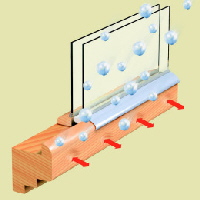

High hailstorm resistance

Varnish film can protect normally only under the circumstances it is undamaged. A severe hailstorm penetrates the film layer and water and moisture can penetrate inside the wood. New resins of generation 3 offer the crack resistance, which can defy the hailstorm.

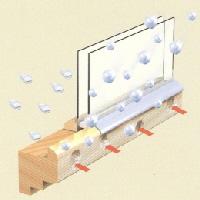

The most modern UV protection

All color shades of varnishes on the window MAKROWIN of generation 3 are improved in pigmentation in order to fulfill most high criterion. Even the most pale color shades can block more than 90% of UV radiation harmful for wood (in blue color on picture).

Equalizing colors

There has to be done much work to equalize and level the places with various suck potential. As result there are impregnations and varnishes they can assure the balanced shade on the problematic wood and on the joined woods as well.